What does IQF stand for?

In the culinary world, IQF stands for “Individually Quick Frozen”. Each portion is frozen separately from the others, which is one characteristic that sets IQF meals apart from other foods. The Individually Quick-Frozen (IQF) technique, also known as flash-freezing, entails placing the food items on a conveyor belt and sending them through a blast chiller, where they are frozen very quickly. The food pieces stay separate after freezing because they are separate when they are put in.

IQF Fruits and Vegetables

IQF fruits are fruits that have been frozen and prepared with IQF technology. Individual fruits are transported through a conveyor belt to a blast freezer in the IQF process, where the fruit is quickly frozen. The fruits are single pieces when they move in, and because of this, they continue to be single pieces even after being frozen, leading to the eventual production of an IQF fruit. The nutritional value of IQF veggies is also retained better than that of conventionally frozen foods. For individuals who desire the convenience of frozen but don’t want to forgo quality or flavor, IQF veggies are a fantastic option.

Fruits and vegetables like maize, peas, and green beans, shellfish like shrimp and scallops, or poultry like individual chicken breasts are typical examples of IQF items. The IQF method is used to treat whole birds, including frozen turkeys.

How Does IQF Function?

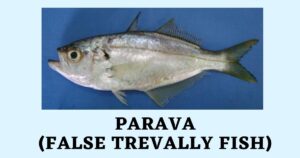

A biologist who was ice fishing in Canada discovered that the fish he fished out of the water below the ice would promptly freeze solid when he threw them on the snow, which led him to invent the method. The fact that some of these fish would remain alive after they thawed was even more amazing.

This unexpected outcome is due to the fact that faster freezing produces smaller ice crystals than slower freezing. Cells and tissue fibers are damaged by larger ice crystals. Some of the fish survived because the ice crystals that formed when the fish froze were too small to damage the cell walls.

With IQF or flash-frozen foods, the same theory is at play. Foods degrade when they are frozen because heavy ice crystals weaken and dry up the food’s fibers, causing it to become limp. The fibers are compressed by the ice crystals, which causes the food’s water content to leak out of the breached cell walls. Small ice crystals are created when foods are frozen quickly; as a result, the food’s fibers are not harmed.

IQF vs Cold Storage

Cold storage freezing and IQF freezing are the two main categories of freezing procedures. These are two entirely distinct approaches, and the results exhibit clear differences. While IQF fruit freezing is used for smaller food items like berries, fruits, veggies, etc., cold store freezing is utilized for large quantities of products like whole chickens, meat, etc. It takes a while for the product to get completely frozen in a cold store.

Advantages of IQF

The product is quickly frozen to the center using the Individually Quick-Frozen (IQF) process. Food safety is one of the most crucial aspects of freezing with IQF technology. In contrast to cold store freezing, where everything must be done manually, IQF technology allows for zero touch between the product and the worker. These elements are anticipated to fuel the demand for IQF fruits.

The ability to keep the food’s quality and freshness is one of its greatest benefits. The food is kept from freezing into a single large clump thanks to the individual flash-freezing procedure.

Rapid freezing produces smaller ice crystals in the frozen meal. The flavor and texture of the meal are preserved as a result. Large ice crystals that form during slower freezing processes might harm the food products’ cell walls, which may have an impact on flavor and texture.

Since IQF food items are always available, they are a practical and cheap choice for people who wish to enjoy fresh, healthy foods without having to worry about food waste. Because of this, IQF veggies are a fantastic choice for anyone who want the convenience of frozen meals without compromising on quality or flavor.

Uses of IQF Fruits and Vegetables

There is no doubt that as its popularity increases, we will see more and more uses in all kinds of food manufacturing and processing. The food sector is using this technology more and more as producers work to offer customers high-quality, fresh frozen goods all year round. It is simple to understand why this technology is growing in popularity, given its many advantages.

IQF foods are already put to use in a variety of ways. The most well-liked programs include:

- Smoothies, juices, and other beverages contain IQF fruits and vegetables.

- Many processed foods and frozen dinners contain ingredients made from frozen fruits and vegetables.

- A lot of individuals use IQF foods as a means to stock up on quick and simple to prepare, wholesome home-cooked meals.

- Many frozen food sections in supermarkets carry IQF products.

- IQF ingredients are frequently used to create convenience dishes like pizza and pastries.

The applications for IQF technology are virtually limitless, and we can only anticipate seeing more and more cutting-edge ones in the years to come.